Profitable While Fluctuating Raw Materials

Visibility to costs and profits across the business enables you to identify issues as they occur, including variations in expected and actual raw material and production costs; late supplier deliveries; obsolete, slow-moving and excessive inventories.

Control Product Design Changes

Your ability to design new products and modify existing designs, as well as improve time-to-market is critical to remaining competitive and profitable.

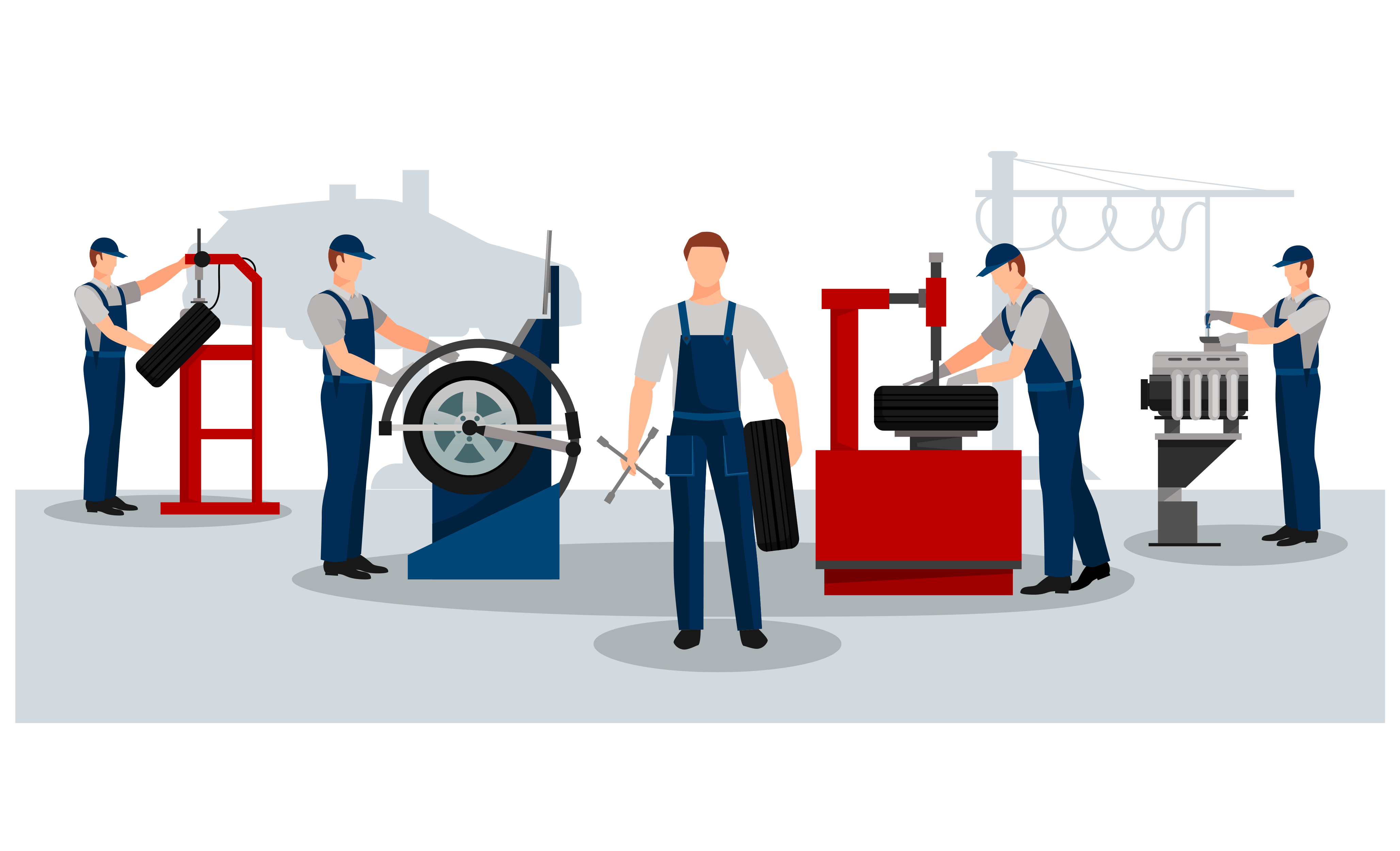

Improve management processes

Easily integrate to supply-chain partners, 3PL and customer electronic ordering and supply systems.

Improve your customer responsiveness in all aspects from design, engineering and configuration.

English

English Arabic (عربي)

Arabic (عربي)